AUS was awarded the AGC 2015 Build Northwest Award Subcontractor -Renovation for the Nine Mile Dam Rehabilitation Project General Construction. This is a yearly event with numerous contractors submitting entries in all categories. The award was received at the Annual AGC Convention in January, 2016.

AUS was awarded the AGC 2015 Build Northwest Award Subcontractor -Renovation for the Nine Mile Dam Rehabilitation Project General Construction. This is a yearly event with numerous contractors submitting entries in all categories. The award was received at the Annual AGC Convention in January, 2016.

Nine Mile Falls Dam is located on the Spokane River and is approximately 16 miles from downtown Spokane, Washington. The dam is owned and operated by the AVISTA Corp. The recent project being worked on is a generator upgrade for Units #1 and #2. Due to mechanical failures and the high cost to repair the early 1900’s vintage generators, units #1 and #2 have not operated for several years.

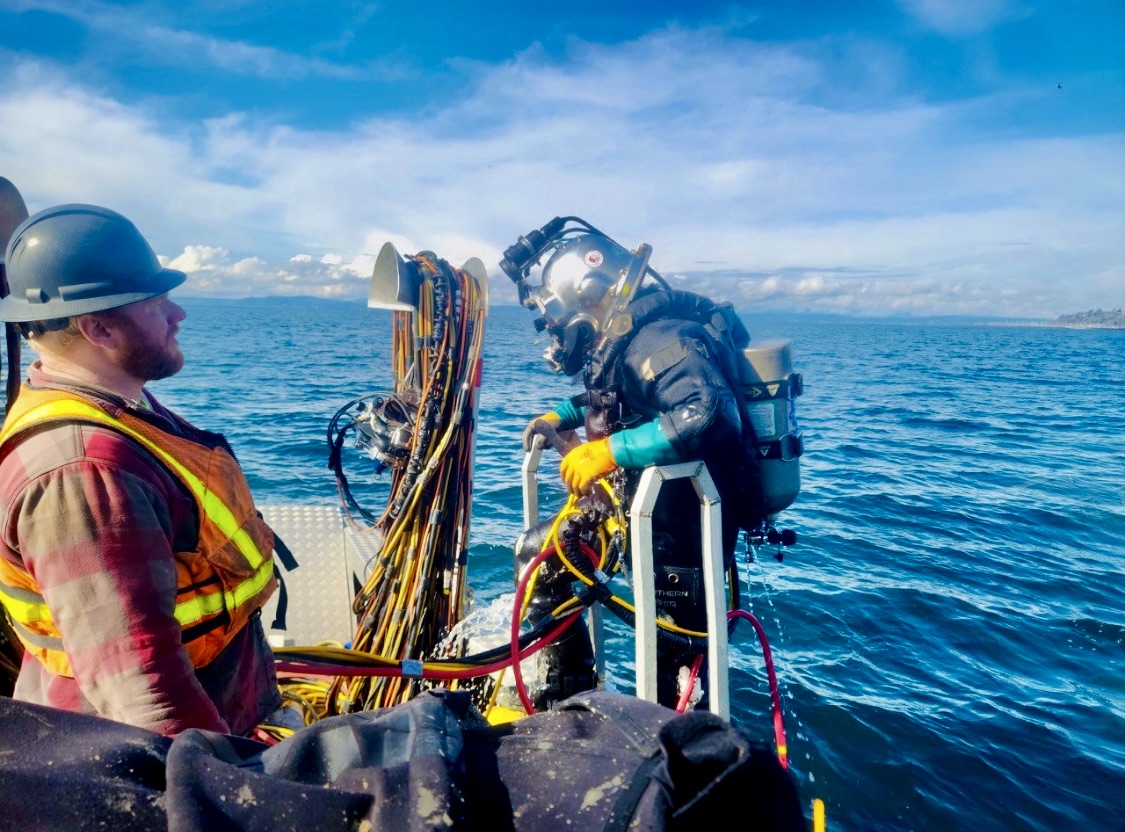

Preliminary underwater work on the project started in 2012 with Associated Underwater Services performing an underwater ROV inspection of the tailrace and inside each of the four draft tubes. One major finding from the inspection was that the #1 and #2 draft tubes were nearly full of sand and debris from not operating for several years.

The generator upgrade contract went out for bid and Max J. Kuney, based out of Spokane, was awarded the contract. Associated Underwater Services was chosen to perform the underwater work. The construction project started in the summer of 2014. The critical path underwater work was to create a dry work area inside Units #1 and #2. This work started with the installation of two dewatering bulkheads upstream. This allowed work to begin on the removal of the old generators and the modification of the penstocks to accept the new generators. Sand removal started during the summer of 2014 and continued throughout the diving project with new sand constantly migrating back into the work area.

The most challenging part of the project was the dewatering of the downstream side of the dam. Working adjacent to the constant flow of water over the spillway created challenges in securing the work barge into position and rough working conditions. To keep the work schedule, AUS provided three dive crews with two day shifts and one night shift. New draft tube stop log guides would need to be installed underwater on the sides of the piers. AUS performed detailed surveys of the existing slots and found that the original guide slots were not in line with each other and they were not plumb. A new design was developed by URS Engineering. The new design required the existing guide slots to be enlarged and new steel guides to be installed inside the larger guide slots. To accomplish this task a wall saw was set up on a vertical track to make vertical cuts in the concrete on both sides of the guide. The concrete was then chipped out by the divers. A bottom sill plate needed to be installed and this required several cuts in the floor to create a keyway for the new bottom sill plate. An underwater core drill was used to drill the holes for the rebar dowels and these were installed with epoxy. The new guide beams were installed in one piece with a full sized alignment frame. Once the new guide was in the slot the entire assembly was jacked into position tight and rock bolted. The grout forms were wet welded into position by the divers. The forms were sealed with Splash Zone Epoxy and then the guides were grouted into position. After the grout cured, the alignment frame was retracted and removed with the crane. New guides were installed in all four draft tubes. New draft tube stop logs were installed in Units #1 and #2 so that those entire units could be dewatered to continue the generator replacement work in the dry. This phase of the underwater work was completed in April of 2015. Work on the generator upgrade is still ongoing.